An efficient solar panel MPPT charger circuit might be developed utilizing a few 555 ICs and a few other linear parts. Let's understand the methods.

An MPPT or Maximum Power Point Tracker for solar panels is a technique which allows deriving highest offered current from a solar panel during the day without troubling its specific voltage, hence enabling supreme effectiveness from the panel.

Of course we all understand, obtaining best performance from any kind of power supply turns into achievable if the process does not include shunting the power supply voltage, which means you should obtain the specific needed lower level of voltage, and optimum current for the load which is being controlled without irritating the source voltage level, and without producing heat.

Quickly, a anxious MPPT ought to permit its output with optimum essential current, any lower level of needed voltage yet ensuring the voltage level across the panel remains unchanged.

One technique which can be mentioned right here includes PWM method which can be certainly one of the maximum techniques to date.

We ought to be grateful to this little genius known as the IC 555 which almost makes all tough ideas appear really easy.

In this particular idea too we include, and intensely rely on a number of IC 555s for applying the MPPT impact.

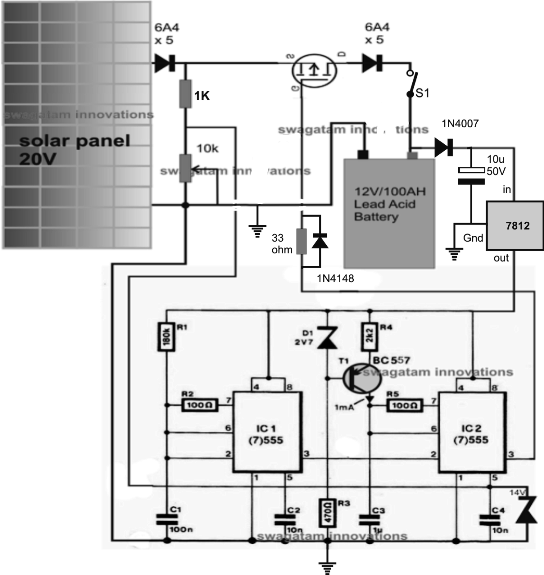

Searching for the presented solar mppt circuit making use of IC555 we observe that the whole design is essentially split into two phases.

The upper voltage regulator stage and the lower PWM generator stage.

The upper stage includes a p-channel mosfet that could be placed as a switch and replies to the utilized PWM info at its gate.

The lower stage is a PWM generator stage. A couple of 555 ICs are set up for the suggested measures.

IC1 is liable for generating the essential square waves which happens to be prepared by the regular current triangle wave generator consisting T1 and the connected elements.

This triangular wave is placed on IC2 for working into the essential PWMs.

In spite of this the PWM spacing from IC2 is determined by the voltage level at its pin#5, which can be resulting from a resistive network across the panel via the 1K resistor and the 10K preset.

The voltage between this network is instantly proportional to the varying panel volts.

In the course of peak voltages the PWMs turn out to be wider and vice versa.

The above PWMs are employed on the mosfet gate which performs and offers the preferred voltage to the attached battery.

As talked about in the past, throughout peak sunshine the panel produces higher level of voltage, higher voltage signifies IC2 producing wider PWMs, which often maintains the mosfe switched OFF for longer periods or turned on for fairly shorter periods, in accordance with an average voltage value that will be simply around 14.4V across the battery terminals.

When the sun shine worsen, the PWMs get correspondingly narrowly spaced permitting the mosfet to perform more so that the average current and voltage across the battery has a tendency to stay at the best values.

The 10K preset ought to be modified for getting around 14.4V across the output terminals under bright sunshine.

The good results could be checked under various sun light situations.

The presented MPPT circuit guarantees a stable charging of the battery, without disturbing or shunting the panel voltage which also leads to lower heat generation.

Note: The associated soar panel will be able to produce 50% more voltage than the connected battery at peak sunshine. The current needs to be 1/5th of the battery AH rating.

A re-designed type of the above design utilizing buck converter may be seen in this post.

The way to Establish the Circuit

It might be completed in the following method:

At first continue S1 switched OFF.

Introduce the panel to peak sunshine, and modify the preset to get the needed maximum charging voltage across the mosfet drain diode output and ground.

The circuit is ready right now.

As soon as this is achieved, turn on S1, the battery will begin obtaining charged in the MPPT mode.

Adding a Current (Error Amplifier) Control Feature

A cautious research of the above circuit reveals that as the mosfet attempts to make up the dropping panel voltage level, it permits the battery to obtain more current from the panel, which impacts the panel voltage dropping it further down activating a run-away circumstance, this might be totally against the MPPT law.

A current control feature as demonstrated right here diagram looks after this issue and does not allow the battery from attracting too much current beyond the stipulated limits. Consequently assists in keeping the panel voltage unaltered.

RX which happens to be the current decreasing resistor could be determined with the aid of the following formulation:

RX = 0.6/I, where I is the stipulated minimum charging current for the linked battery

Hey Swagatam, it’s me again my friend and I’m looking at this schematic with considerations to build and try it. For now, I’m not clear what R value you have shown for R1 as it is not clear in the photo posted even in the enlarged mode. So, what I’m needing to do is construct this circuit to handle 4×100 watt panels for now, as the controller I had been using died. This is the second one of those Alpower cheap import models that advertises MPPT/PWM which is IMOP contradictory. Not sure how it can be both, either one or the other seems plausible. These units do employ an STmicro IC on the board and what appears to be MOSFET reverse flow current protection and nicely designed circuitry however they are in no way up to handling the current they are advertised to handle. I realize the rule of you get what you pay for and by the first week of next month, I intend to purchase a real MPPT system that is programmable, suitable for up to 140VOC and compatible with a range of battery bank voltages from 12 to 48 as far as I can recall, it may work on higher voltages like 72, not sure. However since this is an RV system 12V is what it needs to be. So with MOSFET’s and diodes selected to handle the current levels I’m dealing with, there should be some paralleling of components, FET’s and as the schematic indicates 6A4, those will be changed to larger pieces. I’m wondering if in your OP is the BC547 suitable as a single piece to drive the first MOSFET? I’m going to go with the circuit as shown and test it since I have most components on hand and have no controller to work with for the next 2 or 3 weeks, nothing to loose, nothing tried nothing gained. I have blank double sided copper clad board to work with as well as proto board. Please let me know if you have any additional input on this project.

thank you for sharing this circuite.

please advice if this circuitre limit/stops exactly at 14.4v? (especialy when battery is lifepo4).

please advice if you have tested this circuite and its efficioency?

The circuit has been designed after a lot research and consideration, but has not been tested practically…however I believe it will definitely work if implemented after understanding the concept thoroughly.

yes it will keep the voltage near 14.4V optimally until the sun light drop below 15V