In this post we are going to construct a small greenhouse temperature and humidity controller circuit using Arduino which can self-regulate its temperature and humidity.

What is Greenhouse

Plant life require light, warm conditions, air flow, water, and nourishment to outlive and cultivate; various plants have got diverse specifications for every of such requirements. A greenhouse functions by supplying the very first a couple of specifications for your vegetation, though the final three are under your control.

Supplying Light

Greenhouses are manufactured generally using translucent products, generally by means of either glass or crystal clear plastic material. This provides the plants within optimum access to sunshine, that they can utilize for photosynthesis: mixing carbon dioxide from the atmosphere and energy from sun rays to generate basic sugars, that the plant subsequently makes use of as food.

Normally, plant life require around five hours of sunshine each day, while this may differ according to the form of plant; positioning your greenhouse just where it is going to acquire total sunshine throughout the day will make sure that the plants inside obtain adequate light source.

Supplying Warmth

Greenhouses are warmer compared to outdoors simply because all of that sun rays arriving from the crystal clear glass or plastic walls results in being warmth as soon as it strikes a solid surface area, such as ground or the vegetation within the green house. Light is actually a kind of energy, which explains why plants are able to use it to initiate photosynthesis.

How a greenhouse supplies warmth

Whenever light strikes a solid surface, the area absorbs certain of this energy, transforming it to infrared energy (also known as heat) in the operation - the darker the area, the greater energy it could possibly soak up and transform into heat.

Infrared energy features a distinct "shape" than light energy - what researchers make reference to as wavelength - therefore while light can conveniently move though a greenhouse's glass surfaces, this heat will take more time to get away.

The captured temperature warms the environment within the greenhouse and due to the fact a greenhouse is pretty air-tight, the hotter air keeps inside, increasing the whole building's temperature. This is actually the very same outcome that you have undoubtedly encountered while getting in a car right after it's been being placed in a sunny parking area for a couple hours.

Together with adequate sunshine, the temperature inside a greenhouse could become a lot greater than the outdoor temperature; in reality, on a warm sunlit day you may want to air out the greenhouse all day long to maintain from virtually cooking the vegetation inside. On cloudy days or weeks, less sunshine implies that the greenhouse may warm up considerably more gently, if at all.

For this reason, greenhouses are most successful in places which have a good amount of sunlight.

Apparatus design:

A 100w fan acts as cooling source while the humidity is provided by vaporizer, you may use the vaporizer something similar as shown below.

It produces thick stream of steam which will be inlet to incubator. The steam can be carried via any flexible tube.

The flexible tube can be something similar as shown below:

The DHT11 sensor is heart of the project which may be placed at the middle of any four sides of incubator (inside) but away from the bulb or humidity inlet tube.

CPU fans can be placed as shown in the apparatus design for air circulation. For proper air circulation use at-least two fans pushing the air in opposite direction, for example: one of the CPU fan pushing downwards and another CPU fan pushing upwards.

Most CPU fan works on 12V but at 9V works just fine.

That’s all about the apparatus. Now let’s discuss on the circuit.

Schematic Diagarm:

The above circuit is for Arduino to LCD connection. Adjust 10K potentiometer for adjusting LCD contrast.

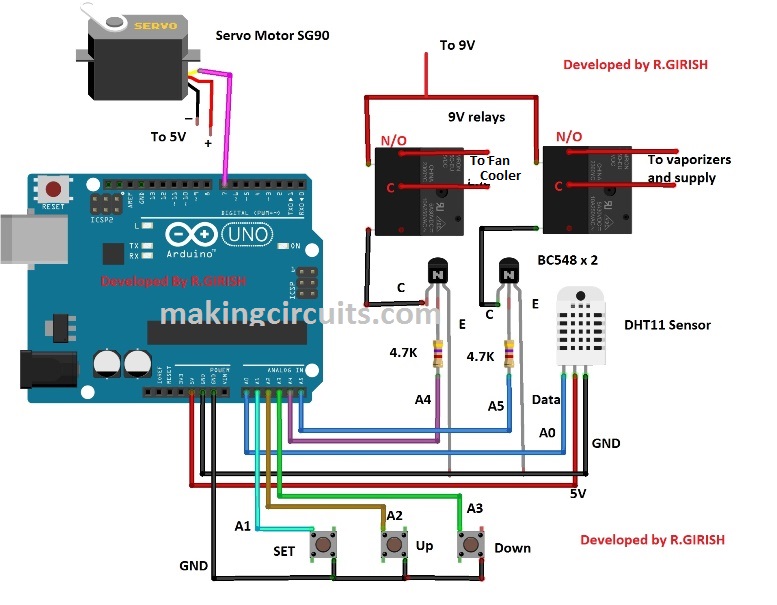

The Arduino is the brain of the project. There are 3 push buttons for setting temperature and humidity. The pin A5 controls the relay for vaporizer and A4 for the bulb. The DHT11 sensor is connected to pin A0. The pins A1, A2 and A3 used for push buttons.

The pin #7 (non-PWM pin) is connected to servo motor’s control wire; multiple servo motors can be connected to pin #7. There is misconception that servo motors works only with PWM pins of Arduino, which is not true. It works happily on non PWM pins too.

Connect a diode 1N4007 across the relay coil in reverse bias to eliminate high voltage spikes while switching on and off.

Power Supply:

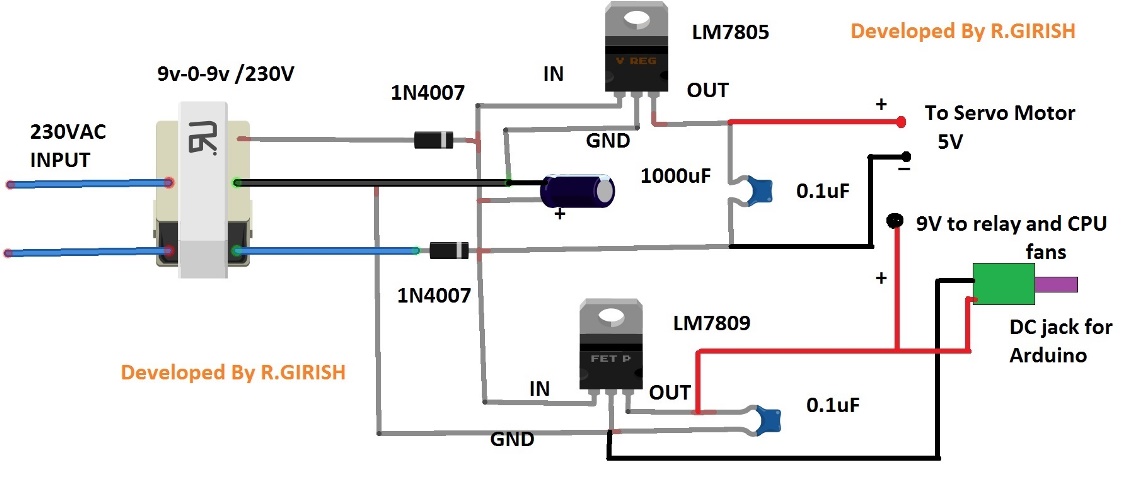

The above power supply will be able to supply 9 V and 5 V supply for the two relays, Arduino, Servo motor (SG90) and CPU fans. The DC jack has been included for powering the Arduino.

Make sure to use heat sinks for the voltage regulators.

That concludes the power supply.

Download the library DHT sensor:

https://arduino-info.wikispaces.com/file/detail/DHT-lib.zip

Program Code:

How to operate this incubator:

· After configuring and finishing the setup, power the circuit ON.

· The display will indicate “set temperature” you must press up or down button to obtain the required temperature and thenpress “set button”.

· After this the display will show “set Humidity” , you can now press up or down buttons to initiate the desired humidity threshold and press “set button”.

· This will set up the functioning of the greenhouse temperature and humidity control.

Please refer to the internet or consult a professional for setting up the right temperature and humidity level for the plants.

If you have any specific question regarding this Arduino greenhouse temperature and humidity controller circuit, feel free to express in the comment section. You may receive a quick reply.

i do the same and nothing happens

nothing reads in serial monitor

please put this question in the Arduino.cc forums, one of the experts may help you to solve the issue!

sir you can give me the library link for this projacte

What is the use of servo motor in this project?

It was earlier designed for an incubator control and now modified for greenhouse…please ignore the servo, or try innovating something from it