The article demonstrates an easy determined configuration which can be employed for applying any specific preferred sized solar panel electricity set up for remotely situated houses or for attaining an off the grid electricity system from solar panels.

36 watts x 2 plus 8 watt provides a total of around 80 watts which can be the total needed consumption level here.

Now since the lights are stipulated to work at mains voltage levels which happens to be 220 V in India, an inverter turns into required for transforming the solar panel voltage to the essential specs for the lights to illuminate.

Also since the inverter requires a battery to operate which may be presumed to be a 12 V battery, all the parameters important for the begin might be measured in the following manner:

Total meant consumption is = 80 watts.

The above power could be used from 6 am to 6 pm which evolves into the maximum period one can estimate, and that's approximately 12 hours.

Multiplying 80 by 12 gives = 960 watt hour.

It suggests that the solar panel might want to generate this much watt hour for the most wanted period of 12 hours during the day. In spite of this considering that we don't anticipate to acquire optimum sunlight by means of the year, we can believe the average period of optimum daylight to be around 8 hours.

Dividing 960 by 8 gives = 120 watts, which means the needed solar panel will have to be a minimum of 120 watt rated.

If the panel voltage is chosen to be around 18 V, the current specs could be 120/18 = 6.66 amps or simply just 7 amps.

Right now let's estimate the battery size which is usually used by the inverter and which can be essential to be charged with the above solar panel.

Again since the total watt hour fr the whole day is worked out to be around 960 watts, dividing this with the battery voltage (which is believed to be 12 V) we get 960/12 = 80, that's around 80 or simply just 100 AH, consequently the essential battery ought to be rated at 12 V, 100 AH to get an an optimal efficiency during the day (12 hours period).

We'll also require a solar charge controller for charging the battery, and since the battery could be charged for the period of around 8 hours, the charging rate will have to be around 8% of the rated AH, that amounts to 80 x 8% = 6.4 amps, for that reason the charge controller will have to be chose to manage no less than 7 amp perfectly for the essential safe charging of the battery.

That concludes the complete solar panel, battery, inverter calculations and this can be effectively executed for almost any equivalent type of set up meant for an off the grid living purpose in rural areas or other remote area. For other V, I specs, the figures might be transformed in the above described calculation for accomplishing the suitable outcomes.

In the event the battery is felt needless and the solar panel may be instantly useful for operating inverter.

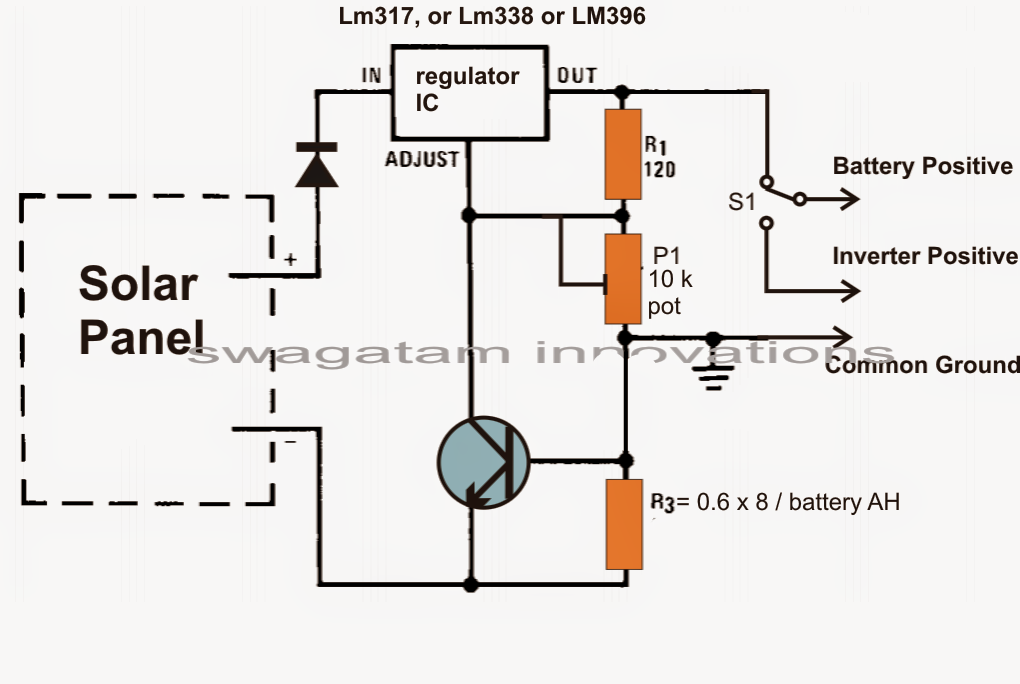

A basic solar panel voltage regulator circuit could be observed in the following diagram, the presented switch can be utilized for choosing a battery charging choice or straight driving the inverter by means of the panel.

In the above situation, the regulator ought to deliver around 7 to 10amps of current consequently an LM396 or LM196 ought to be utilized in the charger stage.

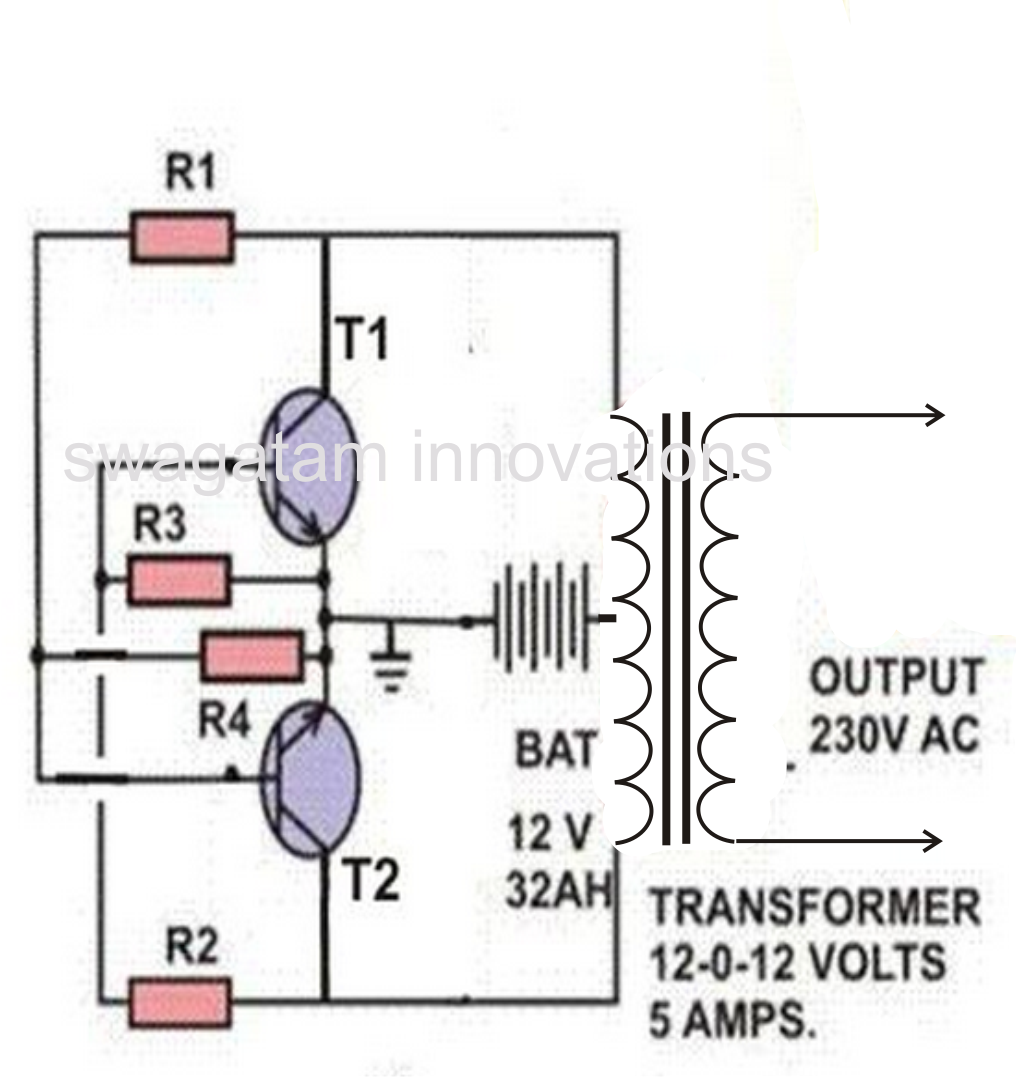

The above solar panel regulator might be set up with the following plain inverter circuit which can be quite sufficient for powering the required lamps by way of the attached solar panel or the battery.

Pats list for the above inverter circuit:

R1, R2 = 100 ohm, 10 watt

R3, R4 = 15 ohm 10 watt

T1, T2 = TIP35 on heatsinks

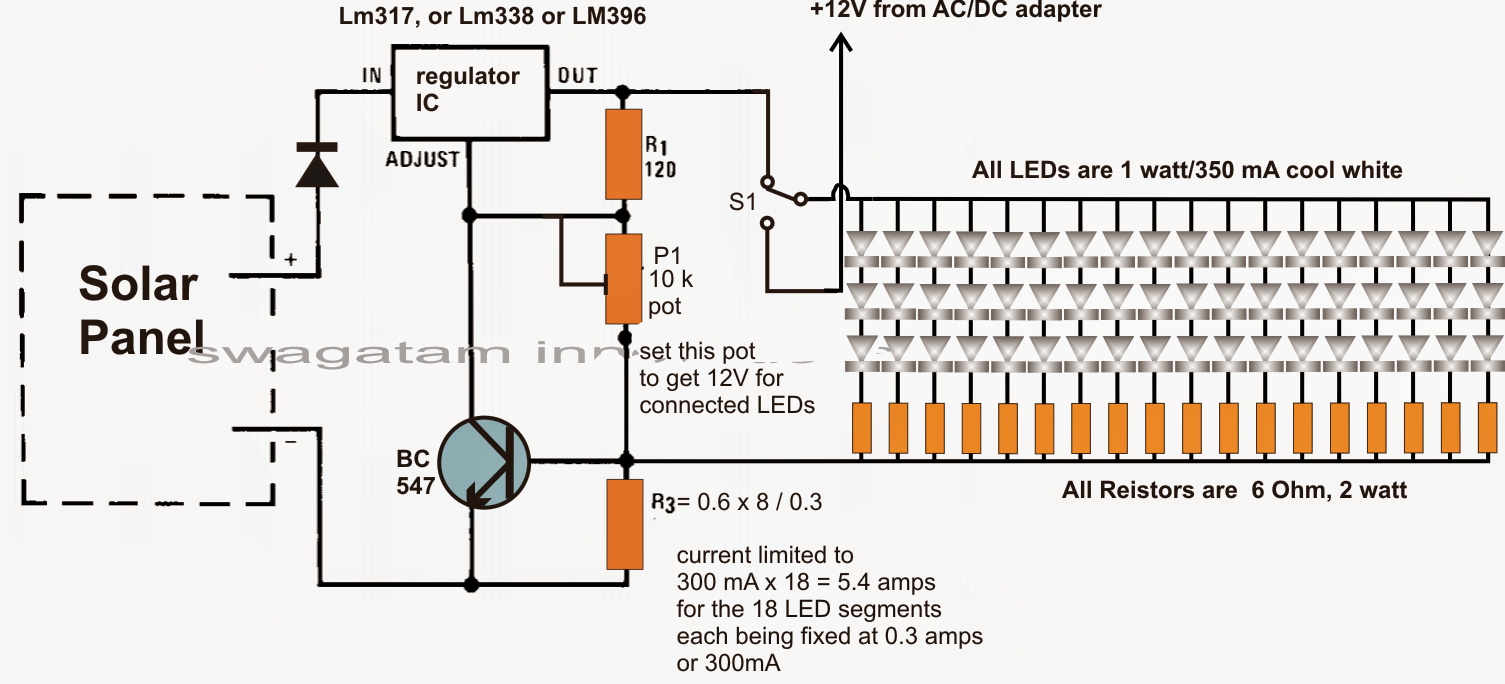

The last line in the request indicates an LED version to be meant for replacing and upgrading the current CFL fluorescent lamps. The same could be executed by means of removing the battery and the inverter and developing the LEDs with the solar regulator output, as demonstrated below:

The negative of the adapter has to be linked and made popular with the negative of the solar panel

Leave a Reply