Every refrigerator has a compressor, generally a hermetically sealed unit with a motor. This unit is the heart of a refrigerator.

As motor burn-out due to any reason can mean a heavy billing on repairing charges, it is wise to invest a little on a protection system.

External protection systems available in the market. unfortunately do not hold good for all types of refrigerators.

Voltage regulators do help but they have their limitations too. Internal (in-built) protection system. which again is a bimetal current relay provided for the motor, is of little help for an ageing compressor.

If. by any reason, the compressor is forced to re-start before attaining an equilibrium, after it has just stopped, the internal bimetal relay trips, sometimes more than twice.

During this tripping the rotor of the motor is left in locked position for about 2 to 5 seconds, each time the relay trips. This is analogous to the short circuited secondary of a transformer. And hence primary, i.e. the motor winding in this case, draws a heavy current.

No doubt the motor is designed to take short while overloads, but too frequent operations of this kind can prove very harmful for the motor.

Providing a time delay for each time the compressor re-starts gives the following advantages: l. Lock-free motor start, leading to a longer motor life.

2. Life of the thermostat switch increases, as power is drawn through this switch a few minutes after it makes the contacts.

3. Defrosting is less frequently required.

4. Providing a fuse specified by the manufacturer almost eliminates the risk of motor burning.

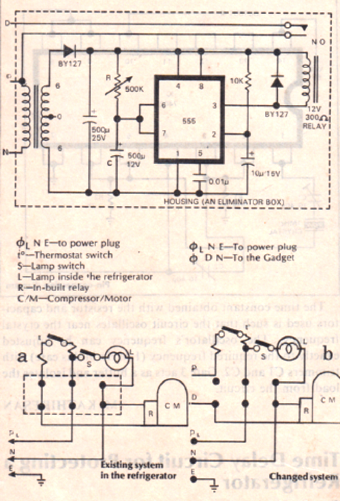

5. A substantial reduction in electricity bill. ” By connecting the circuit shown here, a time delay of up to five minutes can be obtained by varying .

A practical setting of three minutes is however considered ideal for a refrigerator.

Leave a Reply