A resistor is a passive electronic component designed to provide resistance to current in a circuit. There are various forms of resistors. These resistors differ with their structure, power rating, and tolerance levels to numerous factors (for example heat and light). The various types of resistors are as given below:

- Carbon Composition Resistor

- Thermistor

- Wire Wound Resistor

- Metal Film Resistor

- Carbon Film Resistor

- Variable Resistor

- Varistor

- Light Dependent Resistor

Carbon Composition Resistor

A carbon composition resistor (also referred to as a carbon resistor) is the most typically used resistor in electronics.

These types of resistors are usually cheap and easy to produce. Carbon resistors mostly are manufactured from carbon clay arrangement protected through a plastic material enclosure. The terminals of the resistor is built out of tinned copper.

The main features of these resistors are that they're readily accessible from your nearby market and these are extremely sturdy as well. These resistors can be purchased in a many different values.

You will find it as low as 1 Ω value while also with values of up to 20 Mega Ω. Yet the major downside is they are extremely vulnerable to temperature changes.

The tolerance range of these resistors lie around at ± 5 to ± 20 %. These have an inclination of developing RF noise caused by the flow of electrical current across the carbon constituent inside it.

For applications where affordability is the central criteria for creating a circuit rather than high efficiency, these resistors are typically employed.

Carbon resistors come with unique shaded bands printed over their cylindrical body. These color bands are actually color codes for exhibiting or calculating their values and tolerance range.

Thermistor

The phrase thermistor relates to a thermal based resistor. Its resistance changes with respect to temperature changes.

The majority of the thermistors possess a negative temperature coefficient meaning its resistance drops when temperature around it increases.

They are typically manufactured from semiconductor elements. A resistance up to a some mega ohms is normally available for thermistors.

They are utilized for sensing minute variations in temperature.

When it detects a change in ambient temperature, no matter how small, we find a rather substantial enhancement on the value of its resistance.

Wire Wound Resistor

In wire wound resistor a wire made from manganin or constantan is wound over a cylinderical material having high insulation property.

However the main drawback of these types of resistors is the generation of inductance, due to its round coil like shape. Because of this at high frequencies this inductance get significantly large giving rise to other complex issues in the circuit.

The issue is normally corrected by winding opposite turns across the two halves of the unit,, which results in cancelling of the inductance and minimizing its effects. This type of upgraded wire wound resistors become ideal in critical high frequency circuits, but can be costlier for normal circuits.

The temperature coefficient of resistance of manganin and constantan is practically zero.

Therefore, changes in resistance due to temperature variations is found to be minimal for these resistances.

The wire winding is protected with an strong insulation layer that include hardened enamel. This specific insulation is highly resilient to heat and has the property of negating the influence ambient temperature changes.

Various measurements and ratings of wire wound resistor can be simply attained through the use of distinct measures and diameters of the wire Turns.

These types of resistors can be obtained with a wide range of values. The resistance range may vary from 1 Ω to 1 MΩ.

Standard tolerance limitation of these resistors ranges from 0.01 % to 1 %.

They may be applied for high power applications ranging from 10 watt to 200 W power ratings.

The price of these resistors is significantly higher compared to carbon resistors.

Commonly wire wound resistor is needed in areas where carbon resistor would burn due to low power limitations.

Carbon Film Resistors or CFR

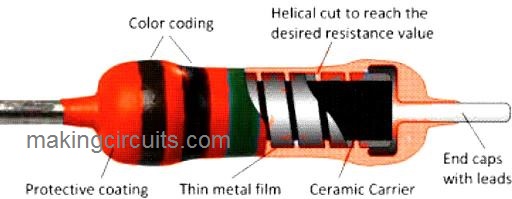

Metal film resistors are manufactured by applying a fine layer of a conductive material like carbon or any similar metal over an insulating base.

The value is established by either trimming the thickness layer or by scraping helical channels with the desired width along the length of the carbon layer.

Metal Film Resistors

In this type of resistors you will find metal caps plugged at the ends of the resistors which are connected to a conductive film with helical grooves.

The end metal caps are fused with the leads of the resistors or the wire terminals.

These are also called metal film resistors or MFR, and could be produced with values as high as 10K MΩ. It's size is much tinier compared to wire wound types.

Their internal configuration is such that no inductance can developed in them and therefore these are pretty accurate with their tolerance level, which is around +/- 1%.

MFRs are normally applied in high precision electronic circuits due to their high tolerance feature.

Variable Resistor

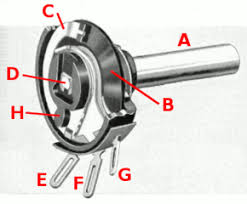

As the name suggests in a variable type of resistors the resistor is adjustable. A potentiometer is an example of a variable resistor.

Image of potentiometer with body disected, showing parts: (A) shaft, (B) stationary carbon composition resistance element, (C) phosphor bronze wiper, (D) shaft attached to wiper, (E, G) terminals connected to ends of resistance element, (F) terminal connected to wiper.

It basically is made up of a central shaft which can be rotated through a wiping movement over a semi-circular flat base contact.

This semi-circular base contact is layered with resistive material, which gives a varying resistance value across the shaft when its moved on this contact.

In its bigger form a variable resistor is named as rheostat. In this equipment a linear sliding contact slides over a resistive elemnt linearly for getting a varying resistance across its termianls.

Non Linear Resistor or Varistor

These form of resistors are also called varistors and are popular for their non-linear V/I characteristic curve.

Due to this attribute the device develops a resistance which is non uniform and apparently does not obey Ohm's law.

These are made up of materials like silicon carbides, zinc oxide.

Basically there are 3 types of varistors in the market:

Silicon carbide disc type varistor

Silicon carbide rod type varistor

Zinc oxide type varistor

Light Dependent Resistor

A light dependent resistors or an LDR has the property of varying its resistance value when light or any of form of illumination is applied on it. Its resistance value drops as the intensity of light on it increases and vice versa.

These are built using the material cadmium sulfide with a smaller quantity of electrons while it's in darkness. This causes a relatively high resistance across its terminals.

However when light falls on an LDR surface, the material reacts with light photons and start ejecting more number of electrons which in turn causes higher conduction across the LDR terminals, subsequently causing a significant drop in its resistance value..

Leave a Reply